The U.S. Department of Labor Mine Safety and Health Administration (MSHA) has issued the following "SAFETY ALERT" in regards to the proper placement of welding leads:

SAFETY ALERT

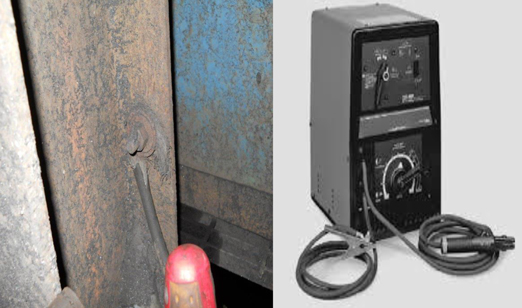

MSHA has been made aware that some surface coal operations have attached the return welding lead to the grounded metal frame of surface structures at the welder. During the welding process, the grounded metal frame of the structure is being used as a current carrying conductor. This practice has led to several accidents and fatalities.

This safety alert is to inform the coal mining community of the hazard of not providing both welding leads as close as practical to the welding area.

A person may become part of the electrical circuit if certain safety procedures are not taken during welding. When a person becomes part of an electric circuit, the severity of the shock is affected by several factors. These include the amount and path of current flowing through the body, and the length of time the body is in the circuit.

The 1968 National Electrical Code (NEC), article 250-21 (Current Over Grounding Conductors) states in part that “grounding of the wiring system shall be so arranged that there will be no objectionable passage of current over the grounding conductors”.

Electric shocks are serious and often fatal accidents. These accidents CAN BE prevented.

BEST PRACTICE

- Attach the work (return) lead as close as practical to the area being welded. This setup shortens the path of current flow between the two leads and helps keep the person who is welding from becoming part of the current path.

REMEMBER: Safety depends upon what you DO or DON’T DO.